astm hardness test pdf|astm rockwell hardness chart : manufacture 1. Scope* tallic materials by the Rockwell indentation hardness prin-ciple. This standard provides the requirements for Rockwell hardness ma. ing the direct and indirect . 15 de fev. de 2023 · 安卓平台 以太PS2模拟器 AetherSX2 安装使用教程. 以太模拟器应该是目前安卓平台上对PS2模拟效果最好的模拟器,可惜的是,因为外界因素,以太模拟器的开发人员无限期暂停了其新版本的开发。. 目前官面如下:. 本次做一个以太模拟器的安装使用教程,算是 .

{plog:ftitle_list}

Paz e adeus. Apoie as editoras e autores de seus mangas e webtoons favoritos, considere ler as séries em suas respectivas plataformas: Leia na MangaPlus!

rockwell hardness testing procedure pdf

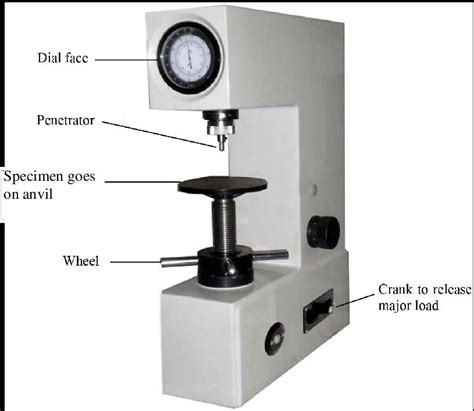

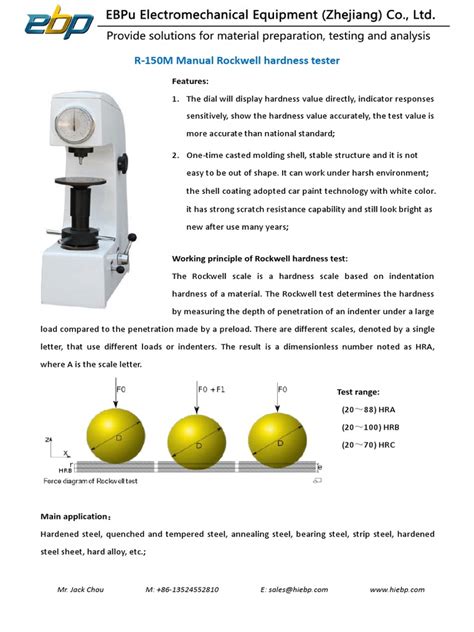

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials by the Rockwell indentation hardness prin-ciple. .4.1 The Brinell hardness test is an indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resis-tance, .1. Scope. 1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness .Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .

1. Scope* tallic materials by the Rockwell indentation hardness prin-ciple. This standard provides the requirements for Rockwell hardness ma. ing the direct and indirect .Hardness Methods: There are several frequently used methods to measure the hardness of metals, including: 1 Rockwell Hardness. The Rockwell hardness test measures the depth of .

portable fuel analyzer

Brinell Hardness Test Schematic Hardness is determined by taking the mean diameter of the indentation and calculating the Brinell hardness number (BHM or HB) by dividing the applied load by the surface area of the indentation . Scope. 1.1 This test method covers determination of the microindentation hardness of materials. 1.2 This test method covers microindentation tests made with Knoop and Vickers .1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments .represented by the test specimens to be considered conforming. Test specimen preparation and hardness tests shall be con-ducted in accordance with Test Methods E18 for Rockwell tests, Test Method E10 for Brinell tests, Test Method E92 for Vickers tests, or Test Method E384 for Microhardness tests.

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .Standard Test Method for Indentation Hardness of Organic Coatings: D2240: Standard Test Method for Rubber Property-Durometer Hardness: D2583: Standard Test Method for Indentation Hardness of Rigid Plastic by Means of a Barcol Impressor: E10: Standard Test Method for Brinell Hardness of Metallic Materials: E18: Standard Test Methods for Rockwell .

5.1 Hardness of a material is a poorly defined term that may have many meanings depending on the type of test performed and the expectations of the person involved. The Leeb hardness test is of the dynamic or rebound type, which primarily depends both on the plastic and on the elastic properties of the material being tested. 1.1 This test method describes a type of composite foam hardness measurement device known as durometer: Type CF. The procedure for determining indentation hardness of substances comprised of two or more elastomeric materials, . Standard Test Method for Indentation Hardness of Aluminum Alloys by Means of a ster Hardness Gage B0647-23 ASTM|B0647-23 . (PDF) format to Licensee and its Authorized Users, who are solely responsible for installing and configuring the appropriate Adobe Acrobat Reader software. . 5.1 For advanced ceramics, Vickers indenters are used to create indentations whose surface-projected diagonals are measured with optical microscopes. The Vickers indenter creates a square impression from which two surface-projected diagonal lengths are measured. Vickers hardness is calculated from the ratio of the applied force to the area of contact of the .

1.1 This test method covers laboratory procedures for determining the scratch hardness of the surfaces of solid materials. Within certain limitations, this test method is applicable to metals, ceramics, polymers, and coated surfaces. The scratch hardness test, as described herein, is not intended to be used as a means to determine coating adhesion, nor is .

5.1 Hardness of a material is a poorly defined term that may have many meanings depending on the type of test performed and the expectations of the person involved. The Leeb hardness test is of the dynamic or rebound type, which primarily depends both on the plastic and on the elastic properties of the material being tested.

Standard Test Method for Film Hardness by Pencil Test D3363-22 ASTM|D3363-22|en-US Standard Test Method for Film Hardness by Pencil Test Standard D3363 Standard Test Method for Film Hardness by Pencil Test> new BOS Vol. 06.01 Committee D01 $ 61.00 In stock . (PDF) format to Licensee and its Authorized Users, who are solely responsible for . Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials E0018-00 ASTM . The use of tungsten carbide balls will provide an improvement to the Rockwell hardness test because of the tendency of steel balls to flatten with use, which results in an erroneously elevated hardness value. . (PDF) format to .%PDF-1.4 %âãÏÓ 1 0 obj /FormType 1 /Subtype /Form /Resources /Font /R8 2 0 R /Ft1 3 0 R >> /ProcSet [/PDF /Text] /ExtGState 4 0 R >> /Type /XObject /BBox [0 0 595 839] /Filter /FlateDecode /Length 283 /Matrix [1 0 0 1 0 0] >> stream xœu MoÂ0 †ïù ïmô ñ± lš4¦} äØK .

rockwell hardness testing guide pdf

Standard Test Method for Film Hardness by Pencil Test D3363-05 ASTM|D3363-05 . of the film hardness of an organic coating on a substrate in terms of drawing leads or pencil leads of known hardness. 1.2 This test method is similar in content (but not technically equivalent) to ISO 15184. . (PDF) format to Licensee and its Authorized Users . Standard Test Method for Portable Hardness Testing by the Ultrasonic Contact Impedance Method A1038-19 ASTM|A1038-19|en-US Standard Test Method for Portable Hardness Testing by the . 4.3 The UCI hardness test may be used on large or small components at various locations. It can be used to make hardness measurements on .

Download Free PDF. Download Free PDF . Procedure 7.1 Magnitude of Test Load—Test loads of 1 kgf to 120 5 ASTM Е 92 TABLE 6 Correction Factors for Use in Vickers Hardness Tests Made on Cylindrical Surfaces TABLE S .test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N), and 150 kgf (1471 N).ASTM B647-10 (R2016) PDF Download Standard EN Preview. Preview. Standard Test Method for Indentation Hardness of Aluminum Alloys by Means of a ster Hardness Gage . ster hardness gages,Aluminum Alloys,Indentation Hardness Test,ster Hardness Tester: ICS Codes: 77.120.10 - Aluminium and aluminium alloys: Language(s) English: File Size . 5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average .

E691 Practice for Conducting an Interlaboratory Study to 3.2.2 microindentation hardness test, n—a hardness test, Determine the Precision of a Test Method 3 normally in the Vickers or Knoop scales, using test forces in 2.2 ISO Standards: the range of 9.807 × 10-3 .hardness (7.3) and scratch hardness (7.4) for each pencil or lead. 8. Report 8.1 Report the following information: 8.1.1 The two end points as follows: 8.1.1.1 Gouge Hardness—The hardest pencil that will leave the film uncut for a stroke length of at least 3 mm (1⁄8 in.). 8.1.1.2 Scratch Hardness—The hardest pencil that will not

2.1 ASTM Standards: E 4 Practices for Force Verification of Testing Machines3 E 140 Hardness Conversion Tables for Metals (Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Rockwell Superficial Hardness, Knoop Hard-ness, and Scleroscope Hardness)3 E 384 Test Method for Microindentation Hardness of Ma-terials3 3 .

Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials E0018-02 ASTM . The use of tungsten carbide balls will provide an improvement to the Rockwell hardness test because of the tendency of steel balls to flatten with use, which results in an erroneously elevated hardness value. . (PDF) format to .ASTM B647-23 pdf free download – Standard Test Method For Indentation Hardness Of Aluminum Alloys By Means Of A ster Hardness Gage. This testing procedure is for assessing the indentation hardness of aluminum alloys using the ster hardness gauge, specifically Model B.

4.1 A Rockwell hardness number is a number derived from the net increase in depth impression as the load on an indenter is increased from a fixed minor load to a major load and then returned to a minor load (Procedure A). A Rockwell alpha (α) hardness number represents the maximum possible remaining travel of a short-stroke machine from the net . 5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average . Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .

astm standards for hardness testing

The Gardner/Sward Hardness Rocker for measuring the hardness of paint and most any other nonmetallic material. +1 (954) 946-9454 . Sward Hardness Test ASTM D2134. . Place the rocker on a test surface and rotate it to the left to an angle greater than where count starts. This is over 22 degrees.

astm rockwell hardness chart

web29 de dez. de 2022 · AIDA64是一款十分全面的测试软件,不但可以查看电脑的具体配置信息,还可以测试电脑的稳定性。使用也比较方便,功能较全面,装机测试、超频测试必备软件之一。

astm hardness test pdf|astm rockwell hardness chart